Precision machining is a manufacturing process that shapes raw materials into precise parts by removing excess material.

It uses computer-controlled tools to produce complex parts, often involving techniques like turning, milling, drilling, and grinding. Precision is crucial for producing parts with tight tolerances, especially in regulated industries like aerospace and medical device manufacturing

Capability overview

- Multi-axis precision machining on mill-turn and universal machining centre platforms

- Multiple kinematics on offer, with and without automated machine tending

- Advanced technology cycles for a range of materials including carbon fibre, high temp superalloys, light alloys, hardened steels, and engineering plastics

- Machine automation - palletising, tending, close loop inspection and control

- Large volume wire EDM

What the AMRF can offer

- Wholistic approach to design for precision machining, from fixturing to inspection

- Advanced CAM programming, offline simulation and post processor development

- Tool path optimisation, dynamic milling optimisation, and process control

- Machining tool performance and failure mode analysis

- Digital production simulation and feasibility studies

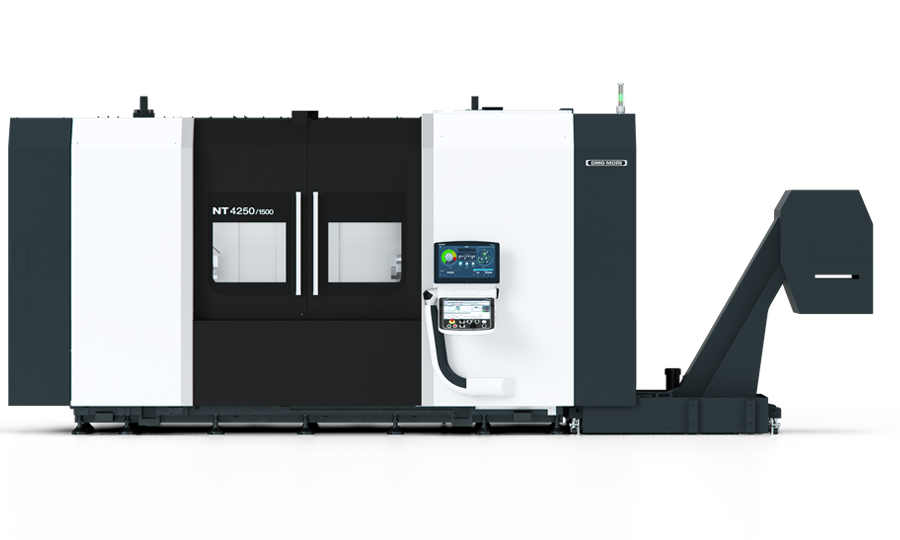

Our specialised precision machining equipment

The mill-turn platform specialises in complex component machining where maximum rigidity and tooling flexibility is mandatory. With a direct-centre-of-gravity kinematic, the mill-turn maintains utmost precision with simultaneous multi-axis control in 8 independent axes, dual spindles, and live tooling on the turret.

Tooling flexibility and an advanced, speedy control prioritises production efficiency when coupled with advanced CAM programming expertise. Flexible fixturing, advanced technology cycles for gear cutting and maximum material removal, and tooling lifecycle analysis are all on offer with the mill-turn platform at the AMRF.

The AMRF performs development to increase material removal rates across a range of technical alloys, programming and tool path development with advanced CAM software, analyses machining economics with a total life cycle approach, and always pushes for complex geometries delivered with maximum productivity and precision.

Access to this equipment will offer you the opportunity to:

- Optimise design for multi-axis precision mill-turn machining

- push tools and programs to the limit across a range of technical metals and alloys

- program gear cutting, y-axis turning, 3-axis turning, and double-sided lower turret live tooling cycles

- experiment with automated machine tending and integrated on-machine verification

How could a mill-turn platform help your business?

Availability of an industry relevant mill-turn can provide you with an opportunity to explore modern multi axis machine tool programming and functionality, offline from your production environment.

By engaging with us through our precision machining and computational design teams, there is an opportunity to explore cost-effective CNC mill-turn options using your own parts.

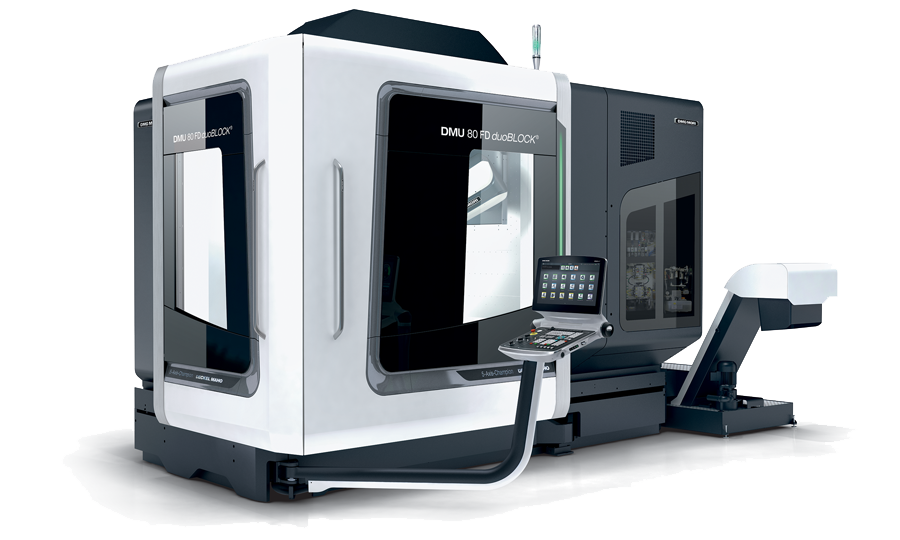

The machining centre available at the AMRF features a novel head rotation to achieve 5-axes of control and an 800 rpm vertical turning table offering flexible, 5-axis precision machining capabilities required for intricate, but large-scale, part development and production.

Accessing this machining centre, presents you with the opportunity to test component designs for machinability and programming development in your manufacturing setting.

Access to our equipment provides you with the opportunity to:

- test combine machining processes on a single platform

- develop know-how and confidence in applying advanced canned cycles

- develop and test fixture design, and integrated inspection

- production optimisation leveraging program simulation, rapid material removal, complex machining, precision finishing and automated tending

How could access to a machining centre help your business?

The option to experiment on a robust 5 axis machining centre through the entire precision machining scope - from bulk roughing cycles to gear cutting, threading, grinding and on machine measurement - can provide you with a highly relevant development platform.

The presence of a wire EDM within the AMRF supports toolmaking, metal additive and machine tool development activities. The high precision cutting of intricate parts in both thick and hard materials make this machining capability an essential process in the manufacturing development environment of the AMRF.

The availability of wire EDM for development work supports application knowledge in both design and machining domains. Large scale EDM access provides opportunity for industry to apply in practice this niche cutting process, leveraging its accuracy and unique capabilities at a relevant scale for many industrial applications.

The benefits of access this piece of equipment include:

- addressing one off production challenges delivering a complex component proving capability and knowhow to and end user.

- learning programming, workpiece setup and process trouble shooting

- part design for EDM, opens new manufacturing possibilities and product form options in high strength materials

How could a wire EDM help your business?

EDM is a specialised precision machining technology which limits access for product development and application knowhow, to those with access to the technology. Enabling large format EDM access through the AMRF supports the application opportunities of this established, yet critical machining technology.

The CMS Kreator is a hybrid machining cell capable of creating large format printed components for end use or tooling applications.

It incorporates a 5-axis simultaneous CNC in a gantry-style kinematic with high-rate fused deposition modelling (FDM) polymer printing.

Creating near-net shapes with the polymer printing head and finishing with 5-axis machining ensures rapid, accurate parts for tooling or critical end-use applications in defence, space, tooling, or plant processing equipment.

Our machine combines polymer printing with five-axis precision machining capabilities. It produces complex geometries by printing large format short fibre reinforced structures, ideal for creating intricate and robust moulds. The combined print and machining functionality enables efficient product development, maximizing productivity.

The gantry design supports a large open working volume for high-speed manufacture with minimal setup. The hybrid capability offers cost effective development of prototype moulds, production parts, and tooling.

The benefits of accessing this equipment include:

- complex part creation on one platform minimising development costs and speed to market

- rapid development of tooling proof of concept from design to finished product

- large format composite mould manufacture in fibre reinforced polymer or aluminium

- rapidly reconfigurable platform for high mix/low quantity of large parts manufacturing

How could a hybrid machining cell help your business?

Scale, flexibility and complementary metrology equipment under the one roof reduces the number of supplier variables to refine when transitioning a product into a commercial production environment.

Availability of this large format machine will offer you a unique product development stepping stone to scale prototypes to production and provide rapid iteration of early stage designs and concepts. Coupled with the hybrid capabilities, this drilling and trimming machine can prove both printing and machining processes on a single platform.

The Hermle C250 HS Flex is built for high-precision 5-axis machining of complex parts where surface quality, accuracy, and repeatability are essential. With a rigid gantry-type design, dynamic drives, and fully integrated automation via the HS Flex handling system, the C250 delivers exceptional performance for lights-out machining and precision component manufacturing.

A high-speed spindle and precision rotary table enable full 5-axis simultaneous machining, making it ideal for complex contours, moulds, aerospace components, and advanced prototype development. Coupled with advanced CAM programming, the C250 allows for efficient tool paths, reduced setup times, and consistent production quality.

At the AMRF, the Hermle C250 supports advanced process development including multi-axis tool path optimisation, dynamic tool engagement strategies, and high-speed finishing in hard-to-machine materials. Integrated probing, tool monitoring, and flexible automation help streamline workflows and improve machining economics.

Access to this equipment will offer you the opportunity to:

- Explore precision 5-axis machining for complex geometries and tight tolerances

- Develop and test advanced CAM strategies for dynamic and high-speed cutting

- Optimise automated machine tending for small-batch or high-mix part production

- Validate on-machine probing and measurement workflows for integrated quality control

How could the Hermle C250 HS Flex support your business?

Access to an industry-leading 5-axis machining centre with automation gives you the chance to refine your advanced machining workflows, test and optimise programs in a low-risk environment, and unlock greater precision, productivity, and consistency.

Connect with our computational design and precision machining teams to explore how advanced 5-axis automation can enhance your manufacturing outcomes.

Want to know more?

Could your machining requirements be met on a single machine tool, but you are uncertain about the combine capabilities, programming skill or the return on investment?

Accelerate your business with the AMRF

Find out more about our services and how the AMRF can help you grow your business.

Check out our full rates and services